Flexible Bags & Pouches

With a wide variety of pouches and bags, we can match you with the right option for your business.

See ProductsFlexible Packaging & Product Packaging Solutions

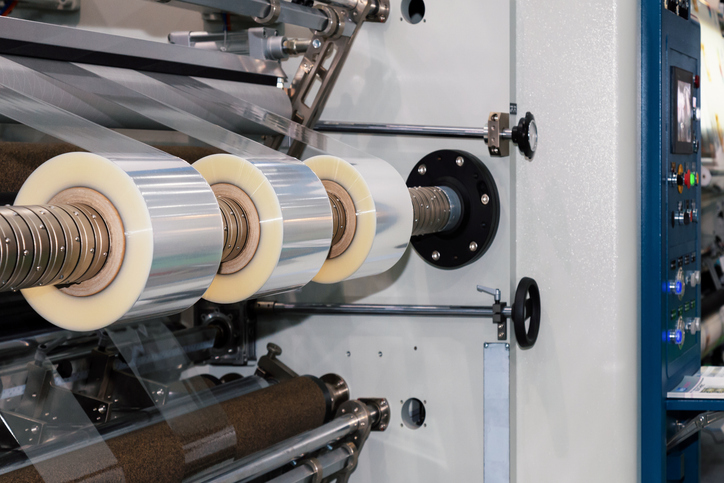

Rollstock Packaging

A versatile and cost-effective option, making it a popular choice for various packaging needs.

See ProductsFlexible Packaging & Product Packaging Solutions

Reclosable Packaging

Perfect for various kinds of products, as it helps maintain freshness and prevents spillage or waste.

See ProductsFlexible Packaging & Product Packaging Solutions

Cleanroom Stock Products

No time to wait for custom packaging solutions? We’ve got a wide variety of stock products for every need.

See ProductsFlexible Packaging & Product Packaging Solutions

Prototype Services

We can create rapid prototypes in days, with quantities as small as one unit.

See ProductsFlexible Packaging & Product Packaging Solutions