Leading the Way With the Latest Eco-Innovations

When you need a sustainable packaging company you can trust, turn to PPC Flex. For decades, we’ve been working with businesses to deliver high-quality sustainable packaging solutions that reduce environmental impact. Whether you’re looking to make the switch to sustainable materials or want an updated option, we’re here to help. Learn more about our sustainable corporate practices below, or reach out to our team with questions.

How We Reduce Your Environmental Impact

We make it a top priority to set a cleaner, greener standard for the packaging industry. As an SQF Level 2 certified sustainable packaging company, you can entrust us to deliver high-quality materials, every time. We use the following processes to reduce environmental impact throughout the manufacturing process.

Laser Anilox Cleaner

We use a laser anilox cleaner to reduce water and energy consumption during our plate cleaning process. Compliant with international safety regulations, this energy-efficient air extraction system eliminates messy waste and facilitates faster cleaning cycles.

Regenerative Thermal Oxidizer

These systems reduce our carbon footprint by destroying any volatile organic compounds (VOCs) that may be created in our manufacturing process. VOCs may include air toxins, odors, and hazardous air pollutants. Exhaust air from industrial processes are redirected into a combustion chamber, where the VOCs are then exposed to extremely high temperatures until the pollutants are 99% destroyed. The result is cleaner air for our employees, communities, and the planet.

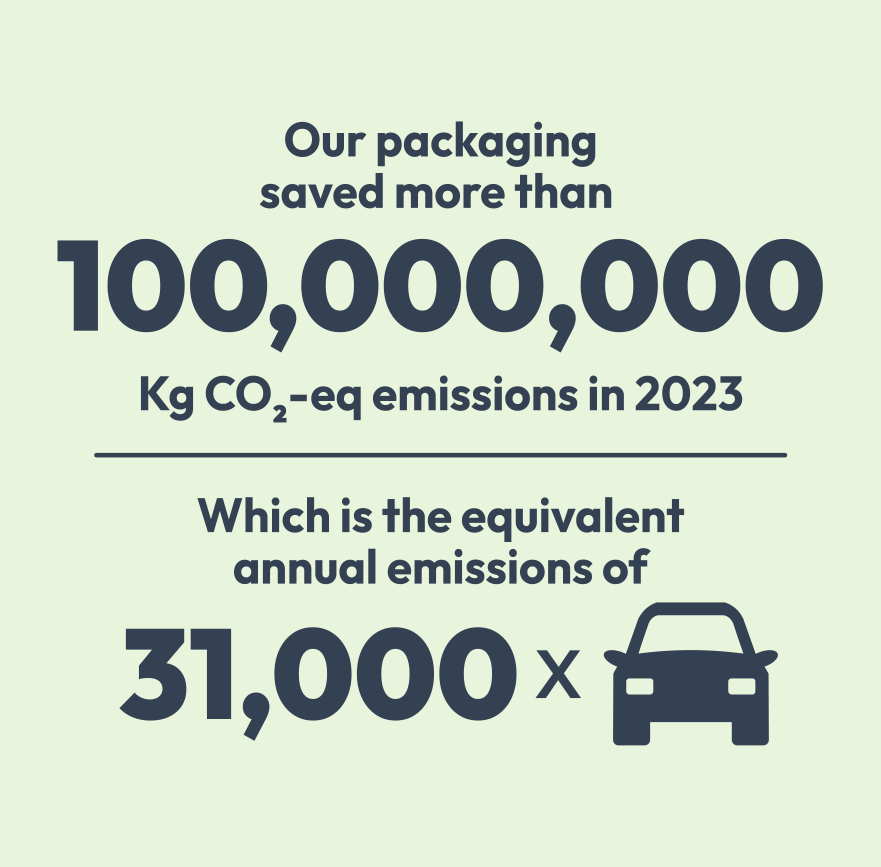

Reducing GHG Emissions

In research conducted at Wageningen Food & Biobased Research facility, Netherlands, it was demonstrated that Xtend®, XflowTM and XgoTM packaging solutions help lower greenhouse gas (GHG) emissions by reducing waste in the fresh produce supply chain and by facilitating sea transport instead of air transport of produce to distant destinations.

The reduction in GHG emissions far exceeds those generated in the lifecycle of the packaging itself.

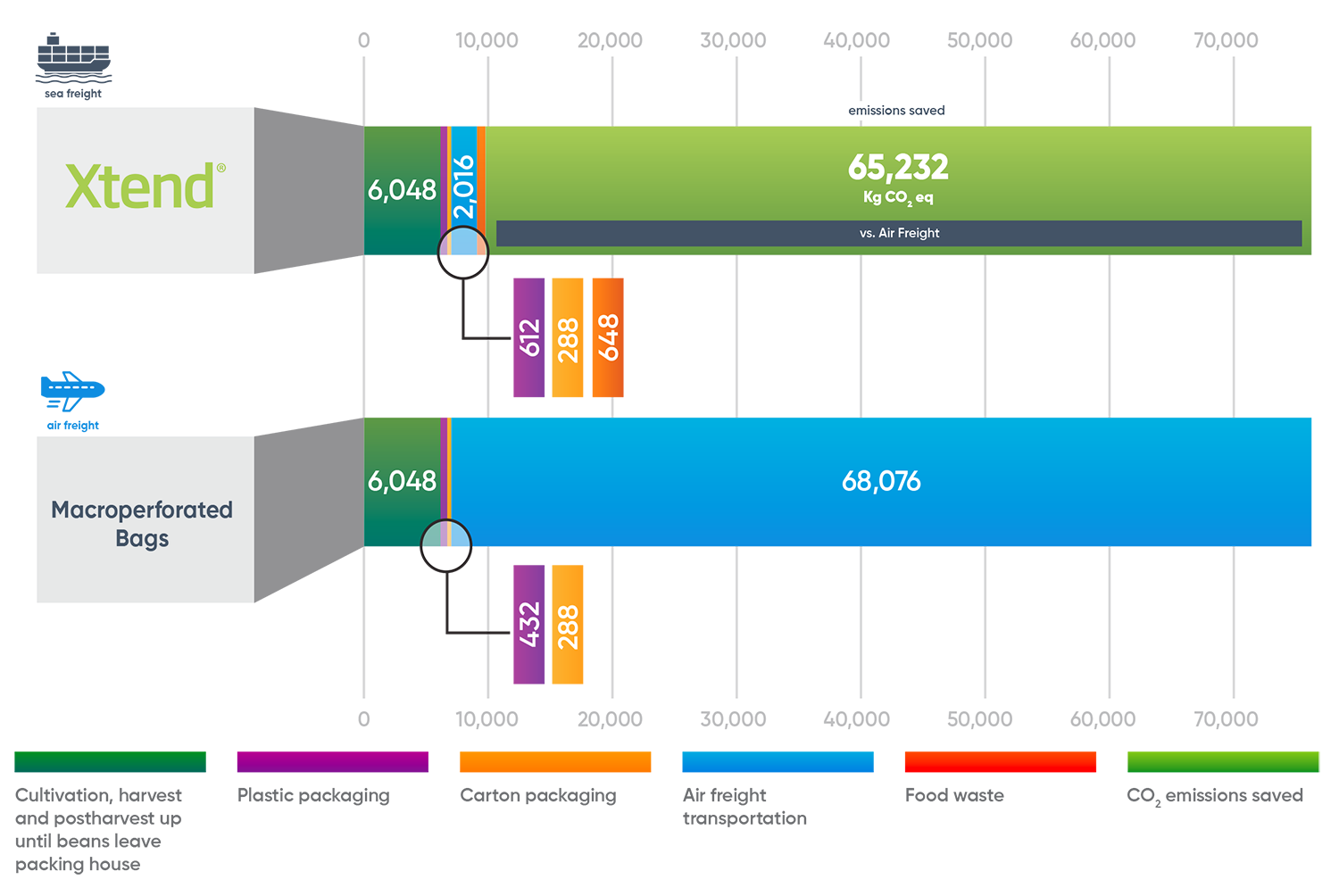

In the example given below, the use of Xtend for green beans shipped from Guatemala to Miami enables transport via container ship instead of by air, reducing the carbon footprint by 65,232 CO2 equivalents per container load, which is equivalent to the annual CO2 emissions of 20 typical passenger vehicles!!!

18 Tons of Beans shipped from Guatemala to Miami

GHG emissions, expressed as Kg CO2 equivalents /40ft container beans

This case study demonstrates how shelf life extension can help reduce food waste and greenhouse gas emissions while also improving business operations and profitability.

Start Working With a Leading Sustainable Packaging Company Today

If you’re ready to enhance your environmental sustainability and appeal to eco-conscious consumers, reach out to us today. We’ve continually improved our sustainable materials and practices to provide the best solutions for our clients. Leveraging state-of-the-art processes, a dedicated team, and multiple industry certifications, we stand ready to meet your specific needs. Get in touch with our team for an initial consultation.