In the world of medical and healthcare packaging, precision is everything. One of the most overlooked yet critical design considerations is the placement of the header strip on a pouch—specifically when used with thermoform trays. A seemingly small decision, such as choosing a top-mounted vs. bottom-mounted header, can make or break functionality, efficiency, and ultimately cost.

Understanding the Issue

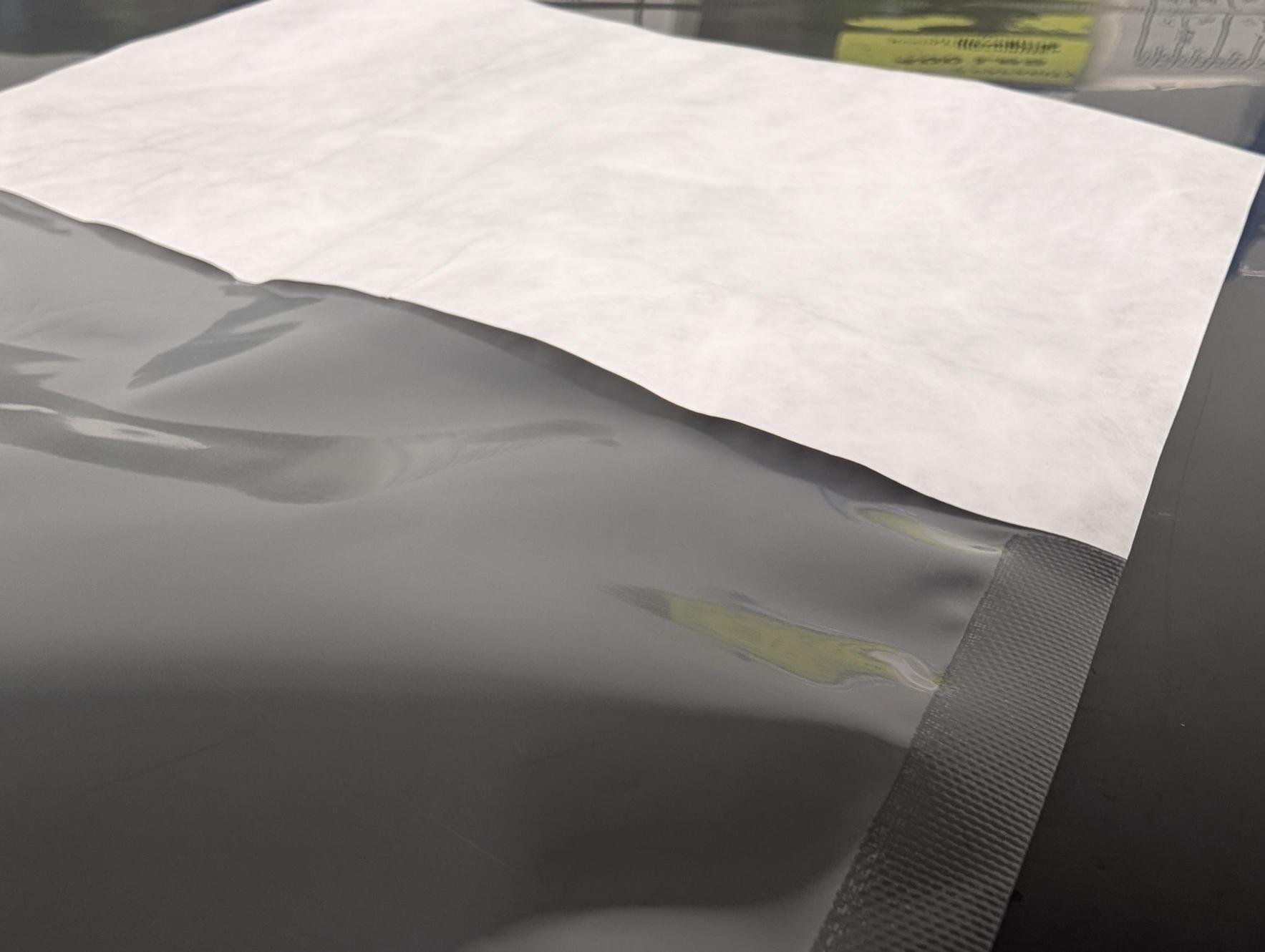

A common mistake in medical device pouch design is the improper placement of the header strip, which can cause thermoform trays to catch or snag as they are inserted into the pouch. This can lead to damage, contamination risk, slowed production, or even rejection of an entire batch.

The core issue? A bottom-mounted header creates a lip that catches on the edge of rigid or semi-rigid trays, disrupting the smooth loading process. This not only slows down automation but can also jeopardize the sterility of the contents—leading to regulatory compliance risks and added costs.

The Smarter Solution: Top-Mounted Headers

Positioning the header at the top of the pouch eliminates interference during tray insertion, allowing for:

• Smooth automation compatibility

• Reduced product damage

• Improved packaging efficiency

• Cleaner presentation and peelability

But as with any packaging decision, context is key. Factors like the shape of the device, automation requirements, sterilization process, and storage conditions must all be considered early in the design process.

How to Prevent Header Strip Errors

Design for the End Product Early

Don’t wait until production to address pouch design. Involve your packaging engineers from the start.

1. Evaluate Tray Interaction

Test how your device tray interacts with pouch prototypes—both manually and via automation.

2. Use a Trusted Partner

At PPC Flex, we offer both top and bottom-mounted header configurations, depending on your product’s needs. Our team can guide you through the optimal design for your tray and sterilization method.

3. Rely on Certified Cleanroom Manufacturing

PPC manufactures in ISO 4 and ISO 7 cleanrooms within an ISO 9001 and ISO 13485-certified facility, ensuring your packaging meets the most stringent quality and regulatory standards.

Let’s Talk

Avoid costly setbacks. Whether you’re developing a new device or revisiting an existing format, our team is here to help.

Let’s schedule a quick call tomorrow morning to discuss your application and determine the best solution.